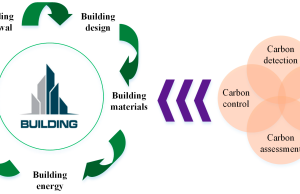

In the wake of the zero carbon buildings framework issued by the Green Buildings Council, sustainable practices are non-negotiable in modern construction.

As developers work to cut carbon emissions and improve on-site efficiency, they’re also redefining longevity for new buildings. With the integration of low-carbon materials and renewable energy systems, we’re starting to see truly resilient built environments.

If you’re working within or alongside the construction sector, here’s what you need to know.

Prioritising lower embodied carbon

The emissions associated with manufacturing, transporting and installing building materials are known as embodied carbon. Reducing this is now a priority, with developers moving away from methods that rely on heavily polluting fossil fuels.

With eco-friendlier choices like timber and recycled materials now on the rise, project managers are starting to lower overall project emissions. By choosing materials with a lower environmental footprint from the outset, the industry builds cleaner foundations for the future.

Reducing waste on-site

Construction waste is a major environmental hurdle. It’s estimated that the industry produces at least 60% of the UK’s total waste, highlighting the sheer size and scale of the task.

In large-scale developments, even the smallest improvements in material efficiency can boost carbon performance. Site managers are increasingly following circular economy principles, which revolve around recycling and repurposing to give consumables the longest possible life.

These goals turn potential waste into a resource, proving that environmental responsibility can be paired with a sensible budget.

Hard-wearing components

Whole-life performance matters most in the process of calculating a building’s carbon output.

Choosing durable, long-lasting components – such as high-quality cladding and fixtures – drastically reduces the need for frequent replacement cycles. For example, in new commercial fit-outs, high-quality UPVC doors offer excellent thermal efficiency and minimal maintenance. They’re also fully recyclable at the end of their long life.

This long life stops the “carbon spike” that happens when new parts are made and put in place every few years. By buying these long-lasting building blocks, developers can work toward a low-carbon strategy that will last for decades.

Leveraging low-carbon technologies

The modern construction site itself is now a testing ground for the very technologies that the finished, cutting-edge buildings will eventually house.

Developers are starting to integrate renewable energy sources and low-carbon tech during the earlier construction phase, along with the final stock. These solutions reduce a project’s dependence on fossil fuels and boost long-term operational efficiency.

From affordable housing schemes to commercial office blocks, these technologies provide a clear pathway to superior energy performance and lower running costs. Alongside lower waste, reduced embodied carbon and durable components, they’re an important part of a much bigger puzzle.