A computer numerical control (CNC) machine is a machine that is pre-programmed using computer software to follow specific manufacturing instructions. These sorts of automated manufacturing machines have been around since the 1940s and 1950s when they relied on telecommunication data storage, rolls of paper punched with holes to represent the inputted data known as “punched tape“. However, technology has moved on, and nowadays, they rely on digital processing power to deliver an accurate automated manufacturing process. Let’s take a closer look and explore what a CNC machine is.

CNC machining has significantly changed the manufacturing industry. The world has become digital and so have our manufacturing plants and processes. CNC machines are progressively becoming smarter, faster and user friendly. These forms of advanced machines can help save your business money and time, helping to make it competitive in an ever-changing industry. It appears that the future of manufacturing will be backed by CNC machining.

How Does CNC Machining Work?

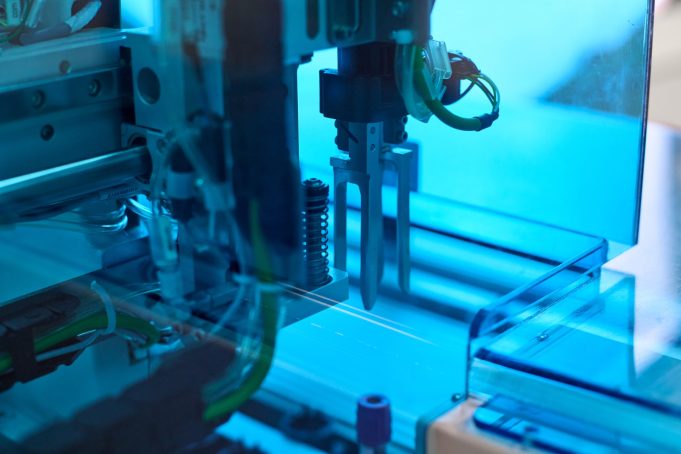

When using a CNC machine, the designer programmes the software to make the desired cuts by the corresponding machines and tools. The instructions work as a road map for the machines to machine the designs. These machines and tools then carry out the specified dimensional tasks just like a robot would.

This ability to programme computers to control and instruct machine cutting reduces the chance of human error and increases the productivity of labour-intensive and highly skilled processes.

There is a range of different automated CNC machines that range from the basic to the complex. Basic machines move on one or two axes, while more complex machines can move laterally, longitudinally and sometimes rotationally. These more advanced CNC machines can eliminate the need for manual workers almost completely.

Types of CNC Machine

Today, most modern CNC machines are entirely electronic, with the most common CNC processes including hole cutting, ultrasonic welding and laser cutting. As you decide what CNC machines to add to your operation, take a look at the most frequently used CNC systems.

CNC Milling Tools

Probably the most common CNC machine out there, the CNC mills use a rotary cutting tool to remove any material from the stock unit. Milling machines can perform various functions, including drilling, cutting gears, boring, and producing slots within a piece of material.

Drills

CNC drills make precision holes by using a rapidly rotating drill bit. This drill bit makes contact with the stationary stock material and produces a hole in the desired location.

CNC Lathes

CNC lathes are essentially the opposite of a drill. These machines spin the block of stock material against the drill bit. Lathes typically make lateral contact with the material, with the cutting tool moving laterally until it touches the spinning stock material.

Water Jet Cutters

CNC water jet cutters are tools used to cut hard materials like metal and granite. These cutters use a powerful jet of water, occasionally mixed with other materials, such as sand and other abrasive materials, to carve or cut certain materials.

Water jet cutters are generally used as a cooler alternative to other heat-intensive CNC machines. These cutters are also usually used for applications requiring more intricate cuts, as the lack of heat means that the material’s intrinsic properties don’t change.

Plasma Cutters

Plasma cutters cut materials by using a plasma torch. The plasma is produced using a combination of electrical arcs and compressed-air gas. This form of cutting is generally applied to metal materials but can be used on a range of materials.

Electric Discharge Machines

The use of electric discharge machines (EDMs) is occasionally referred to as spark machining and die sinking. With EDM, two electrodes produce current discharges between them, which allows the material to be processed into particular shapes.

As the electrodes move closer together, it produces an even stronger electric field. This allows the current to pass between the electrodes, and each electrode removes portions of the material.

Materials Used for CNC Machining

One of the best things about CNC machining is that nearly any material can be used in a CNC machine. The main thing to remember is that it all depends on the application. Common materials used include metals such as aluminium, copper, titanium, brass, steel, and other materials like wood, fibreglass, and plastics like polypropylene.