Electrical discharge machining has become popular in most production industries like the health sector, automotive industry, and aerospace, among others.

This machinery helps achieve precise dimensions regardless of the strength of the material. Erosion of complex and tough materials is also done with this tool.

With that said, let us dig deeper into the advantages of using electric discharge machining services.

Cost-effective

EDM machining works on almost all electrical conductors regardless of how hard or fragile they are. Plus, it is a speedy process and can be completed at a go.

Likewise, EDM saves you more on materials by producing lesser waste. You can even apply it to exotic materials and make fine cuts at a very low cost.

Complex materials like hard metals can easily be drilled through without pre-heating and do not require cleaning up after machining. Generally, you can save a lot with this machinery and still get quality end-products.

High tolerances

Most engineers believe that EDM machining produces better and more accurate cuttings than plasma, laser, or flame cut.

The reason being, it doesn’t exert too much pressure on the parts. Additionally, thanks to its high tolerances, this machining can achieve an accurate fit and precise dimensions.

Moreover, the quality of the parts is higher and better than any other machinery. This means your final pieces will not require additional finishing and processing.

Fast processing

Cutting and shaping hard metals is a tough job. Luckily, thanks to electric discharge machining, this process has become much easier and manageable.

You can have the job done within minutes without damaging or distorting the parts. Plus, it only takes one-step processing to get all the essential parts that you need. This saves both time and money.

Create complex shapes

When it comes to convenience, electrical discharge machining beats all the other conventional cutting tools.

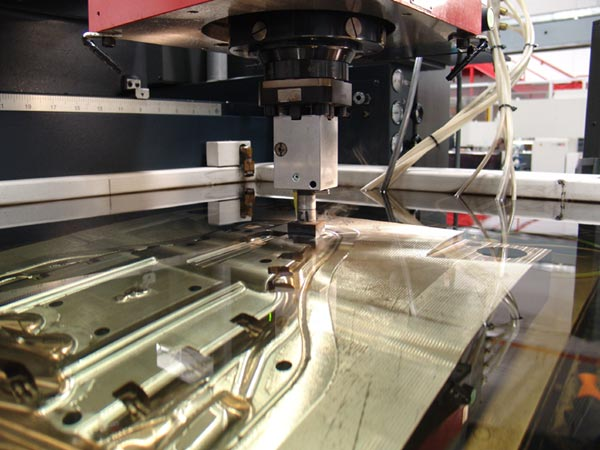

Be it cutting small pieces or molding multifaceted shapes, this machinery can do all that in limited a time. The tool discharges strong electrical currents through a thin wire, making it capable of cutting even the most fragile or hardest material.

Similarly, the machine’s high tolerance allows it to produce multiple shapes of different sizes, and soften or harden the material. Read more here.

Good finishing

Initially, most blacksmiths used to apply tremendous force on hard metals to create good finishing. Nevertheless, these may have some major drawbacks.

Your material may end up distorted or worn out from the impact. It is also the reason why traditional tools are not ideal for fragile materials.

On the other hand, EDM is specially designed to handle delicate and brittle materials without direct contact between the workpiece and the machine. Besides, very little or no polishing is required on the resulting parts.

Creating fine holes

As long as the materials are electrically conductive, you can easily create neat and fine openings on the workpiece. The cutting wire on the electric discharge machining is perfectly designed to make holes of different widths without any mechanical stress.

Industries using EDM

Now that you know the benefits of electric discharge machining, let’s look at some of the industries that use this machinery.

Medical device manufacturing

This tool can be used to shape and cut a wide range of metals without pre-heating. This makes it ideal for manufacturing medical instruments like the life support machines made from carbon steel

Automotive industry

In today’s business world, a good piece of machinery is necessary for fast turnovers and cutting costs. This is why most motor industries are turning to EDM machining.

Military and aerospace applications

This machinery helps in the creation of delicate parts for certain equipment used in aerospace and the military.

Tool, die and mold making

The fact that this tool can be used to make fine holes on parts makes it the perfect option for manufacturing custom tools, molds dies, and fixtures. Click here to read more.

Conclusion

The benefits of EDM cutting are the main reasons why most companies are ditching traditional metal cutting tools. Nevertheless, metal cutting requires the help of professionals before you begin your project. Therefore, make sure your blacksmith provides efficient and high-quality services before choosing him. It is also good to note that, this machining process only works on materials that conduct electricity.